Continuous 3D printing - Efficient production with high component variety

Ref.-No. F-0209

Keywords: Continous 3d printing, additive manufacturing, production process optimisation, FDM, FFF

With growing globalization and digitalization leading to shorter product life cycles while also expanding the variety of products and product variants, 3D printing technology is seeing increasing use in production processes. It offers a greater level of geometric freedom and especially saves on extremely expensive tool molds. To make 3D printing in mass production profitable and efficient, the 3D printer’s available build area must be fully utilized.

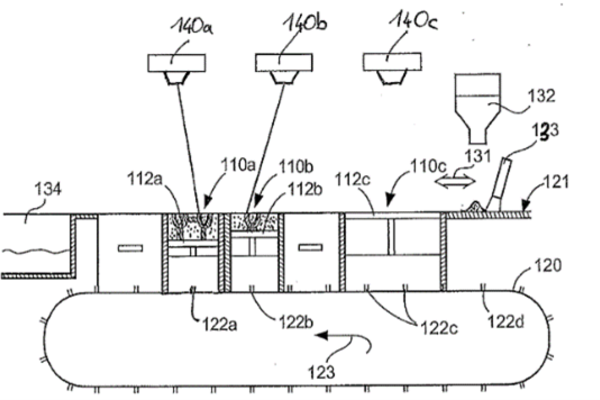

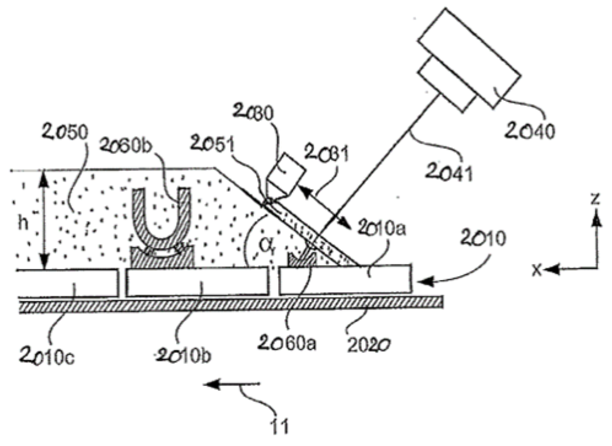

An invention by BEGO Medical offers a novel solution: Either the material is applied on an angled build surface that moves horizontally (as shown in Figure 1); or 3D printing can take place continuously in a kind of conveyor system (see Figure 2), where the freshly printed components can be continuously added.

Competitive Advantages

- Continuous 3D printing

- Suitable for high variety of products and variants

- No batch processing

- Reduced delivery times

- No limit to structural length

Commercial Opportunities

This method makes it possible to mass-produce components in a profitable way despite a wide variety of geometries—something that is necessary for components in industries such as medical technology, which need to be adapted to specific structures or the body's geometry (orthodontic appliances, sports equipment, etc.). Even for small-batch production or especially for intermittent orders, this “3D printing assembly line” is of enormous technical and commercial benefit, particularly as it makes it possible to manufacture components of any structural length.

Current Status

Third parties have already implemented the first solution option using binder jetting and FDM printing processes. Products manufactured with this process are already on the market. The second solution option has undergone feasibility studies that substantiate the practicability of multi-jet printing. This option has only to be commercialized. Both of these options also offer the potential to utilize other suitable 3D printing technologies. These solution options are protected by an existing patent family* to which we are offering commercial licenses on behalf of BEGO Medical.

*EP2681034B1, EP3456513B1, JP6625717B2, CN1036355305, US9456884B2, US10548695B2, US20200229905A1

—

An invention of BEGO Medical GmbH.