WiMDaD Wire Mesh Damage Detection - Comprehensive damage detection in composite materials

Ref.-No. 4585

Keywords: Diode matrix, sensor, break, break sensor, GfK, CfK, composite, wind force, wind energy, measuring method, measuring system, measure, detection, cracks, verification, invention

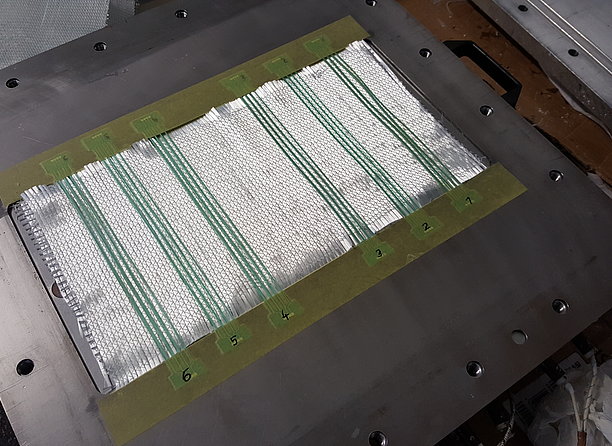

Composite materials are nowadays used in many technical fields. Blades of wind power plants or aircraft parts, for example, are made out of these materials. In order to detect possible cracks or fractures, however, an immense effort is necessary. Conventional methods of material testing such as ultrasound, X-ray or thermography are very time-consuming, if they are possible to employ whatsoever. Other methods such as the use of strain gauges or glass fiber based systems can take measurements permanently, but they can only indirectly detect a fracture in the material. The invention is a novel, continuous measuring method, which is also suitable in particular for large-area applications such as, for example, wind turbine blades. The sensor consists of a braid of wires whose breaking behavior corresponds to that of the fibers in the composite material. The crossing points are connected via diodes. An electronic evaluation unit can switch between electrical paths through specific diodes so that the defective part can be identified in the breaking event.

Competitive Advantages

- Cost-effective

- High temporal resolution

- Continuous measurement

- Early detection of damage

Commercial Opportunities

WiMDaD is a measuring system which can be used especially in large-area parts made out of a composite material. The measuring grid of the invention is inserted into the respective component during the production process. The measurement can take place in intervals set by the user so that continuous monitoring is possible. Particularly in the case of wind power plants, checking the wings periodically is extremely complex and also dangerous. Nevertheless, there are always breaks in the entire wings. With the invention, even small cracks can be detected, so that a replacement can be done before the wing breaks.

Current Status

A German patent application was submitted to the DPMA. In the name of the University of Applied Sciences at Cologne, PROvendis offers interested companies the possibility of licensing and further developing.

—

An invention of TH Köln.