Color flop effects without interference pigments - Cost-effective creation of color flop effects

Ref.-No. F-0155

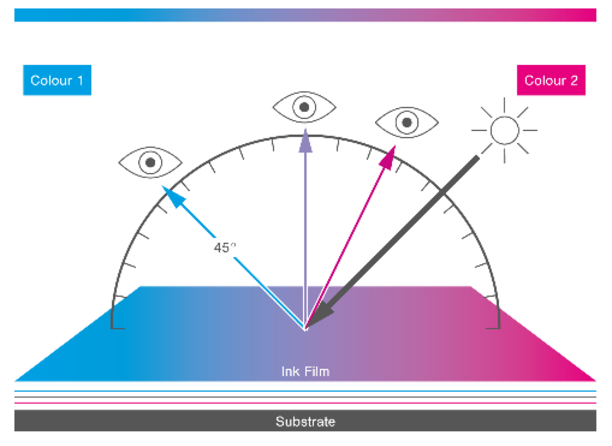

It is an innovative, cost-effective application method for the creation of color flop effects by means of effect pigments without costly interference pigments. In particular, this concerns a special method of applying different pigmented layers and layers with metal effect pigments on top of each other. This method makes it possible to produce different, adjustable color flops (color impression that depends on the viewing angle) without expensive interference pigments. The color flop effects can be created with standard paints or varnishes if they are applied one after the other in a suitable sequence. It is essential that the bottom layer always represents a reflective white layer. Good results are particularly achieved if the bottom layer contains pigments of titanium dioxide, barium sulfate, zinc oxide, zinc sulfide, calcium carbonate, aluminum oxide, aluminum silicate and any combination of these substances.

Competitive Advantages

- Cost-effective: without expensive interference pigments

- Easy integration into processes

- Low manufacturing costs

- Calculable color flops

- Different color flops in different places

Commercial Opportunities

This process is particularly suitable for printing processes or spraying applications where the surface to be printed consists of a light-colored, as white as possible, and even substrate material. This can include foil, film, paper, cardboard, ink, glass, nonwoven material, textile, silicone, metal, or wood.The method is characterized by its versatility and universal applicability, as different color flops can be achieved depending on the structure and sequence of the individual layers. The color flop effect can be calculated, precisely adjusted and reproduced using color data measured at different viewing angles. It is also possible to vary color flop effects across the surface of the substrate material.

Current Status

A European patent application was filed for the invention in February 2018, from which two PCT applications were generated in 2019. Positive search reports are available for both PCT applications. In addition, a patent application for the method of creating a defined color flop using a kind of calculator was filed in mid-2019. Extensive evidence has been provided to demonstrate the function of the specific color flop and variability in print applications as well as spray applications.

Relevant Puclications

EP3524647A1: Ink Layer Sequence with colour flop effect without containing interference pigments.

EP19190181.8: Method for determining the composition of a multi-layer system showing a predetermined colour flip-flop effect, unpublished.

—

An invention of the hubergroup Deutschland GmbH.