WOOD-INSERT - Wood insert for lightweight construction elements in furniture construction and interior fittings

Ref.-No. 5001

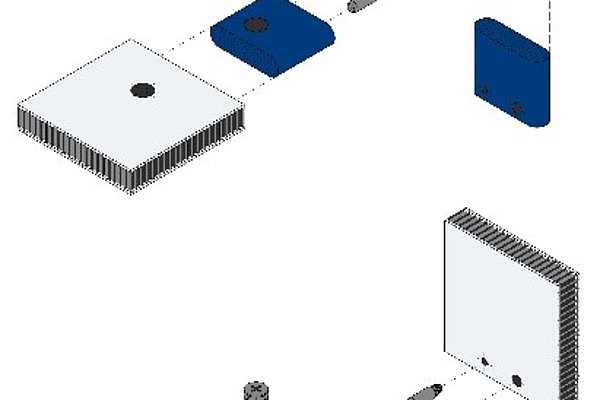

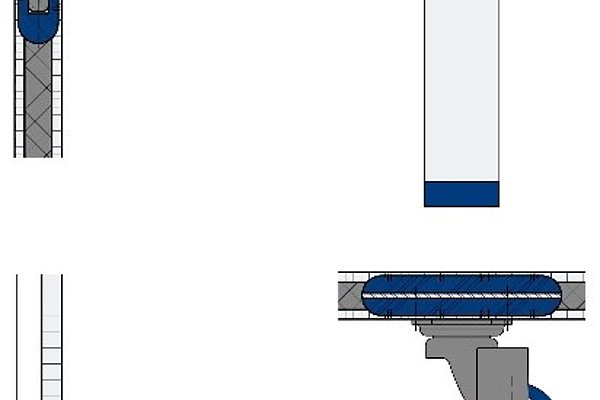

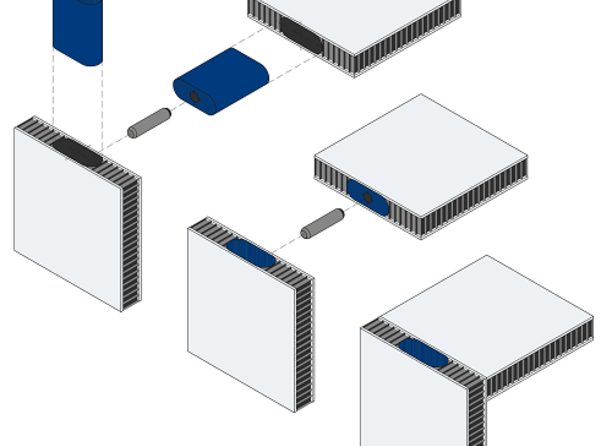

Scientists from the Ostwestfalen-Lippe University of Applied Sciences have developed a wood or wood-based material insert for the partial reinforcement of panel-shaped lightweight construction elements in sandwich construction that can be inserted using conventional tools, hand tools, machines or machining centers. In the reinforced area, where WOOD-INSERT interlocks into the soft core of the lightweight construction element between the upper and lower surface, it creates conditions that even surpass classic wood-based materials. This is achieved by the the insert, which is glued into the soft part on the front side, having approximately the same dimension as the distance between the face layers of the panel. The cut-out is chosen in such a way that both sandwich face layers are included in the adhesion and the WOOD-INSERT edge is flush with the narrow edge of each lightweight construction element when inserted. This means that the narrow.

Competitive Advantages

- Wood/wood-based material insert for sandwich Panels

- Interlocking adhesion bond without foreign materials

- Suitable for individually formatted Panels

- Can be inserted directly into open narrow edges

- Suitable for glued constructions as well as for disassembled construction with Fittings

- Different profiles and sizes possible

Commercial Opportunities

Panel-shaped lightweight construction elements in sandwich construction are increasingly used in furniture construction and interior fittings, with the elements being preferably formatted from a large panel. Due to the soft core, simple wooden dowels such as those used for classic wood-based materials cannot be used for sandwich panels. The same applies to connecting fittings or the screw mounting of attachments. WOOD-INSERT now allows firmly glued, doweled joints of individually cut sandwich panels without prior narrow edge sealing. In addition, WOOD-INSERT also enables the attachment of any fittings, in particular the invisible positioning of the connector in the core layer of the sandwich panel. Since WOOD-INSERT is preferably manufactured from wood material, the finished workpiece does not contain any foreign materials made of plastic or metal, thus enabling environmentally friendly disposal.

Current Status

A patent application for WOOD-INSERT has been filed with the German Patent and Trade Mark Office. International patents are possible. The connecting element was able to demonstrate its advantages in practical tests. A multitude of data and prototypes are available.

—

An invention of TH OWL.