Seal effectiveness doubled - For plastic flanges and other flange connections

Ref.-No. 5558

Keywords: Seal, gasket, flange, plastic

In practical sealing of plastic flanges, there are frequent problems with leaks resulting from creep relaxation, ageing, and unsuitable seal design. And there are large differences in thermal expansion coefficients between the seal and the flange or liner material. Existing seals made of rubber or rubber and steel are subject to ageing, and seals based on PTFE exhibit major creep. Rubber-steel seals, which are frequently used, have the disadvantage of rubber ageing, and the steel core can usually not be positioned precisely in the seal.

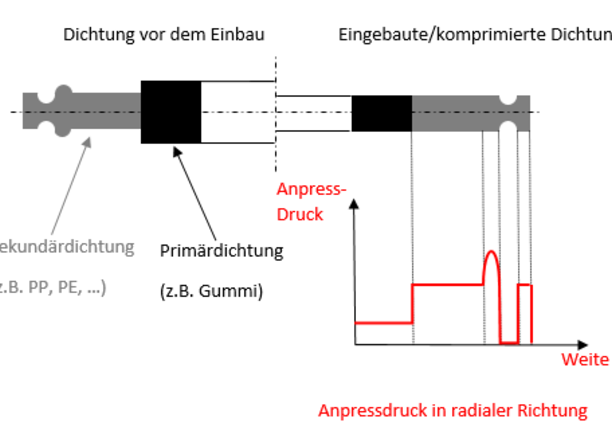

So FH Münster has developed an improved seal. The concept involves two independent gaskets (primary and secondary) in a single setup. The primary gasket (usually oriented towards the medium) can typically be made of rubber, PTFE, or another material. The secondary gasket is made of a material that corresponds to the flange or flange liner material. This sealing part creates a force shunt that keeps dynamic loads from the primary gasket.

Competitive Advantages

- Two independently functioning seals in a single setup

- Leaks are avoided

- Little force required

- Especially well-suited to plastic flanges

Commercial Opportunities

Such seals are especially well-suited to plastic flanges. Material similarity avoids different expansion between flange and seal under thermal load. The setup involves two independently functioning seals. This redundancy provides additional security. The force shunt prevents dynamic loads from being applied.

Current Status

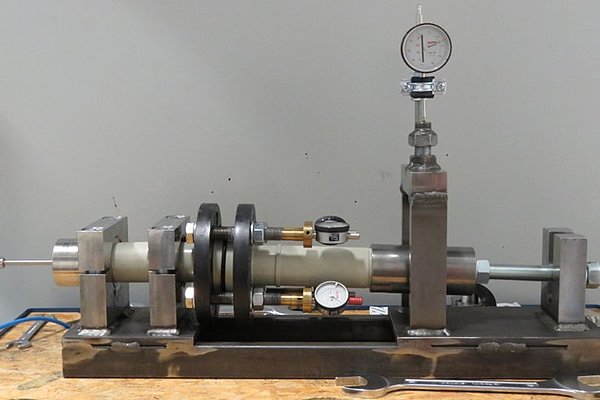

Various seal designs have been prepared. The expected contact pressure adjustment process has been confirmed in simulation. Analytical calculation has been used to design and build a test bench. Extensive seal measurements have been performed. They confirm the advantages of the system.

The seal, planned as an injection-molded part, will now be refined to market readiness in cooperation with Paderborn University (KTP). Patents have been applied for in Europe and obtained in the U.S. At the behest of FH Münster, PROvendis offers interested companies licenses to the invention and the opportunity for technology refinement.

Technology Readiness Level

1

2

3

4

5

6

7

8

9

Technology validated in lab

Relevant Puclications

F. Bartmann, D. Funke, A. Riedl: Anwendung numerischer Simulationen zur Entwicklung innovativer Lösungen in der Dichtungstechnik

XXI. Dichtungskolloqium der FH Münster, Vulkan-Verlag, Steinfurt 2021

—

An invention from FH Münster.