Optimized radial compressor - Moving blades expand the operating area

Ref.-No. 6381

Keywords: Radial compressor, partload, diffusor, low-solidity-diffusor, vaned diffusor

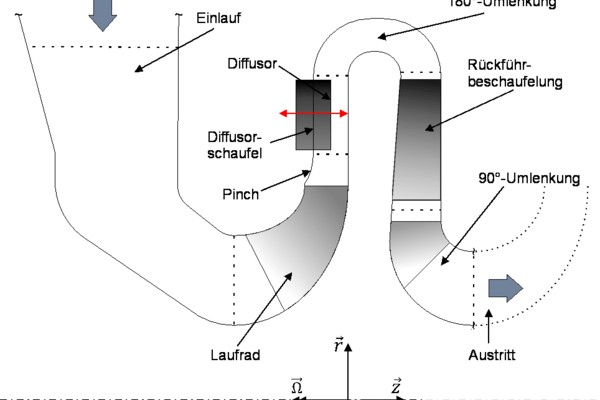

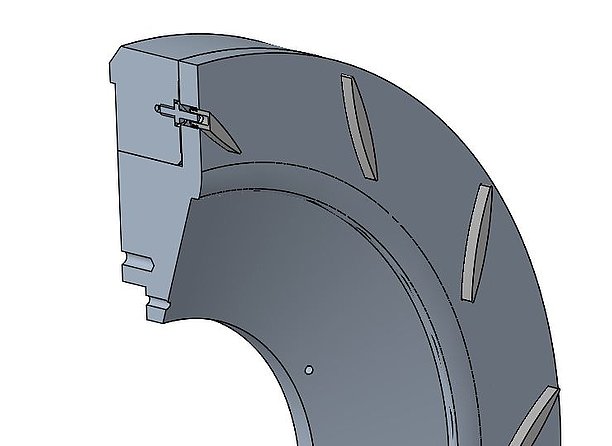

Compressors are at the center of many industrial processes: Their job is to reliably compress gases and increase gas density without requiring much maintenance. Unlike axial compressors, radial compressors have a radial diffuser that can have a bladed or unbladed design. Unbladed radial diffusers allow a greater machine working area, since the cross-sectional area through which flow passes is greater. Bladed diffusers limit the working area because the blades reduce the cross-section. They do guide flow better in the partial-load range with the additional guide blades and can thus achieve higher efficiency. The University of Duisburg-Essen’s invention uses a parallel-walled radial compressor diffuser that works with moving blades: The operating area is expanded, and partial-load operation is more efficient. The blades can be sunk in a side wall recess, where there is a gap between the blade base and the bottom of the recess. If a pre-determined diffuser pressure level is reached, the blades are extended, stabilizing flow and increasing efficiency. For moving blades, intermediate positions are also conceivable, as is extension of individual blades as needed for different operating points.

Competitive Advantages

- Broad work area

- Enhanced efficiency

- Flexible machine operation

Commercial Opportunities

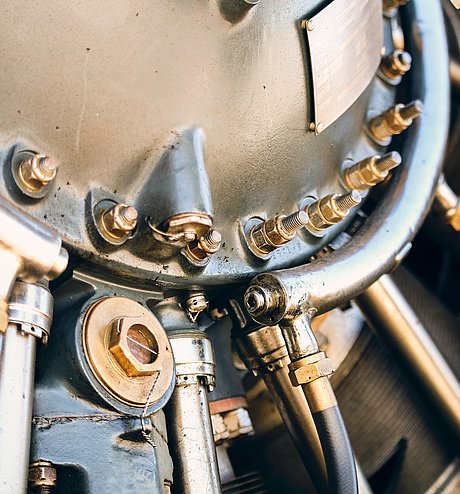

The University of Duisburg-Essen’s technology can be used across industries, including in industrial compressors, turbochargers, and aircraft engines. The moving blades allow a broader working area and greatly increase overall compressor efficiency.

Current Status

The invention has been reported to the German Patent and Trade Mark Office, and further subsequent foreign applications can be submitted in the priority year. Technology function is simulated in a computer. Initial laboratory samples are to be created in 2023. On behalf of the University of Duisburg-Essen, we are offering interested companies the opportunity to license this technology and cooperate with the inventors at the University of Duisburg-Essen in its refinement.

Technology Readiness Level

1

2

3

4

5

6

7

8

9

Experimental proof of concept

—

An invention from the University of Duisburg-Essen.